Safety Testing

Exploring new approaches to safety testing and QC release

Tozaro is exploring new approaches to accelerate and simplify safety testing and QC release procedures. In CGTs, there is a greater need for rapid and effective safety testing to ensure timely patient administration. Current safety testing is stringent; however this can lead to delays in product release. As the number of approved therapies increases, processes need to be streamlined to give faster results with the same levels of accuracy the industry has come to expect.

Tackling the overuse of horseshoe crabs in endotoxin testing

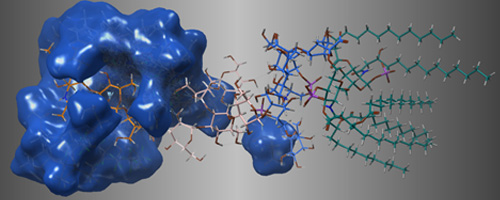

The Limulus Amebocyte Lysate (LAL) assay is commonly used to measure endotoxin with suitable sensitivity. However, this method relies on the blood of horseshoe crabs, introducing animal derived components, whilst also negatively impacting their populations. Tozaro is hoping to tackle this by developing smart polymers that can be integrated into existing analytical technologies such as BLI and SPR to accurately monitor endotoxin and streamline safety testing.

Making contaminant removal a possibility with smart polymers

For complex contaminants, detection rather than removal has often been the preferred approach for cell and gene therapy manufacturers. However, this can be costly; retained process related impurities can lead to the loss of entire batches and delayed treatments. As Tozaro develops solutions for safety testing, the potential for contaminant removal solutions is also a consideration. We are designing our smart polymers with this in mind, to allow us to proceed on this next step of the journey in the future.

Why choose smart polymers?

Designed in silico.

- Our pioneering computational chemistry means we can screen the full virus surface to identify optimally exposed epitopes and produce synthetic affinity reagents that are truly novel.

- We have access to over 600 monomer building blocks (versus the traditional 20 amino acids) allowing us to build-in the exact functionality needed for the application.

Synthesized chemically.

- The chemical manufacturing process of smart polymers means we can deliver a new wave of synthetic affinity reagents that go beyond the capabilities of biologics, providing safe, reproducible and scalable affinity solutions to our clients.

- Smart polymers are free of Animal Derived Components (ADCs), reducing the risk of leached ligands on product quality and safety.

- Robust purification formats allow for sterilization, increased cleanability and re-use potential.

Deployed with confidence.

- Smart polymers offer new solutions to solving high value bioprocessing challenges for our clients. We are using our technology to go beyond what is currently possible.

- Large batch sizes, rapid scale up and manufacturing consistency means clients can depend on the smart polymer supply chain.